LanguageJP/EN

BUSINESS

TECHNOLOGY

We are a one-stop shop for design, prototyping, and mass production based on "cold forging" technology. We also have many secondary processing facilities such as cutting, grinding, and pressing to achieve high precision and low cost for special parts.

High-precision craftsmanship with no grinding produced by skilled techniques and experience

High-precision craftsmanship with no grinding produced by skilled techniques and experience

What is Cold Forgigng

This is a processing technology in which metal is sandwiched between metal molds and compression molded at room temperature. This is an old and new technology to produce tens to hundreds of pieces per minute with "high productivity" while maintaining "high accuracy" by processing at room temperature, and to manufacture "resource-saving" products that meet the needs of the times by compression molding without producing scrap metal.

-

COLD

FORGINGThis is a processing technology in which metal is sandwiched between metal molds and compression molded at room temperature. This is an old and new technology to produce tens to hundreds of pieces per minute with "high productivity" while maintaining "high accuracy" by processing at room temperature, and to manufacture "resource-saving" products that meet the needs of the times by compression molding without producing scrap metal.

-

PRESSING

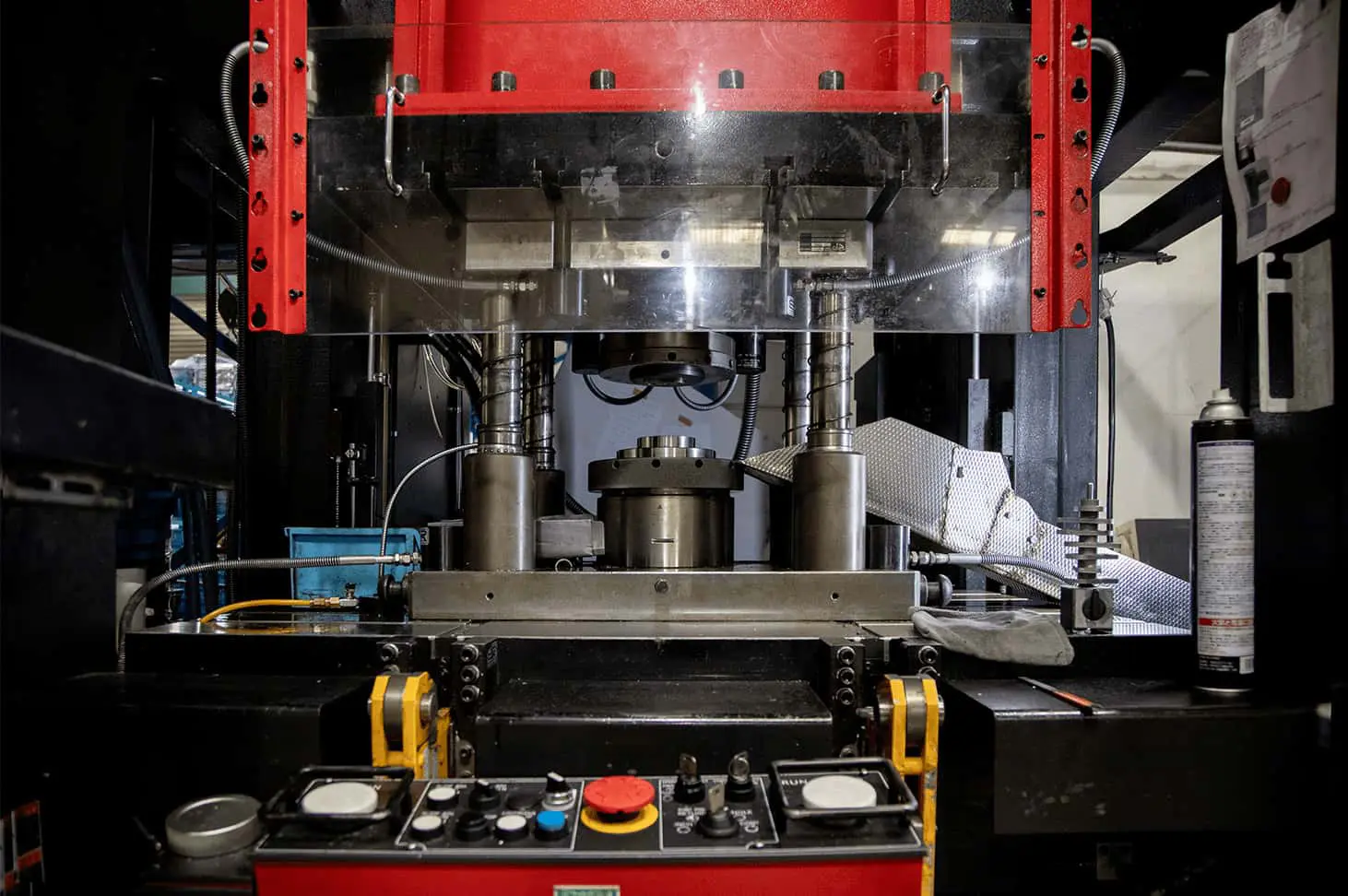

One of the processing technologies of cold forging. It is a processing technology that compresses and forms at room temperature. While the former used in cold heading is driven sideways, the press is driven vertically, and processing is performed without defying gravity, enabling more precise processing. Also, by using a workpiece manufactured by cold heading as a material, more complex shapes can be processed.

-

CUTTING

AND

GRINDINGA machining technique to grind and polish workpieces while producing scraps. Minamida has a variety of processing machines such as lathes, machining, centerless grinding, cylindrical grinding, etc., and performs finish processing of workpieces that have been pushed to the limit by cold forging, responding to manufacturing that is becoming more sophisticated year by year.

-

ROLLING

AND

TAPPINGA processing technology for forming screws and serrations on workpieces manufactured by cold forging to fasten or engage with counterparts. In rolling, two flat and round dies are used to form screws and serrations on the outer diameter of the workpiece. Tapping uses a special tool to form threads on the inside diameter of the workpiece.

-

HEAT

TREAT

MENTA processing method that improves the strength, hardness, and toughness of workpieces by heating metals at high temperatures. Taking advantage of our location in eastern Osaka where many heat treatment companies are located, we can provide various heat treatments such as quenching and tempering, carburizing, nitriding, high frequency, spheroidizing annealing, and softening annealing.

-

SURFACE

TREAT

MENTPlating and coating are processing methods to improve the corrosion resistance, hardness, and appearance of workpieces. Taking advantage of our location in eastern Osaka where various surface treatment companies gather, we can provide various surface treatments such as zinc, nickel, tin, alloy, Geomet, anodized aluminum, anti-sticking, and spatter treatment.